2. According to the center distance, there are: 25, 30, 40, 50, 63, 75, 90, 105, 110, 130, 150 series.

Single stage transmission ratio series: 5, 7.5, 10, 15, 20, 25, 30, 40, 50, 60, 80, 100.

2. The mounting on the machine must be stable and avoid any vibration.

3. Check the correct input efficiency, speed of rotation and output torque according to unit nameplate, and the same direction of rotation of the reduction unit output shaft before fitting the unit to the machine.

4. For a shaft mounting, for reduction unit with a hollow output shaft, make sure that the constraint is axially free and with such play as to ensure free movement for the reduction unit.

5. The various parts ( pulleys,gear wheels,couplings,shafts,etc . ) must be mounted on the solid or hollow shafts using special threaded holes or other systems that anyhow ensure correct operation units. Lubrication the surfaces in contact to avoid seizure or oxidation.

6. After mounting,rotating shaft by hand must be agility and no lock.

7. Staring must take place gradually , without immediately applying the maximum load,and ensure stable,no noise,no loosen,no leaking oil and so on in rotation.

2. During the early stages of service , problem of lubrication may arise due to the high level of viscosity taken on by the oil and so it is wise to have a few minutes of rotation under no load.

3. In the case of particularly lengthy period of storage (4~6 months),if the oil seal is not immersed in the lubricant inside the unit,it is recommended to change it since the rubber could stick to the shaft or may even have lost the elasticity it needs to function properly.

4. Check the correct level of the lubricant through the indicator, if there is one.

5. The oil needs to be changed after approximately 10000 hours. This period depends on the type of service and the environment where this reduction unit works.

6. For units supplied without oil plugs,lubrication is permanent and so they need no servicing.

1. Avoid to hit the shell of the reduction unit by gravitational hammer to protect it.

2. Check the correct state of installation basis,oil seals,input / output shaft and so on in the same period .Otherwise,it is necessary to stop reduction unit and get rid of matter,then go on work.

3. Whenever possible, protect the reduction unit against solar radiation and bad weather.

4. Ensure the motor cools correctly by assuring good passage of air from the fan side.

Recommendation of lubricant brand:

8MRV110~150 | 8MRV025~105 | ||

Mineral oil | Synthetic oil | ||

T℃ ISO VG | (-5)~(+40) ISO VG46 | (-15)~(+15) ISO VG220 | (-25)~(+50) ISO VG320 |

AGIP | BLASIA 460 | BLASIA 220 | TELIUM VSF320 |

SHELL | OMALA OIL460 | OMALA OIL220 | TIVELA OIL SC320 |

ESSO | SPARTAN EP460 | SPARTAN EP220 | S220 |

MOBIL | MOBIL GEAR634 | MOBIL GEAR630 | GLYGOYLE 320 |

CASTROL | ALPHA MAX460 | ALPHA MAX220 | ALPHASYN PG320 |

BP | ENERGOL GR-XP460 | ENERGOL GR-XP220 | ENERGOL SG-XP320 |

The quantity of oil:(liter)

8MRV | 025 | 030 | 040 | 050 | 063 | 075 | 090 | 105 | 110 | 130 | 150 |

B3 | 0.02 | 0.04 | 0.08 | 0.15 | 0.3 | 0.55 | 1 | 1.6 | 3 | 4.5 | 7 |

B8 | 2.2 | 3.3 | 5.1 | ||||||||

B6-B7 | 2.5 | 3.5 | 5.4 | ||||||||

V5 | 3 | 4.5 | 7 | ||||||||

V6 | 2.2 | 3.3 | 5.1 |

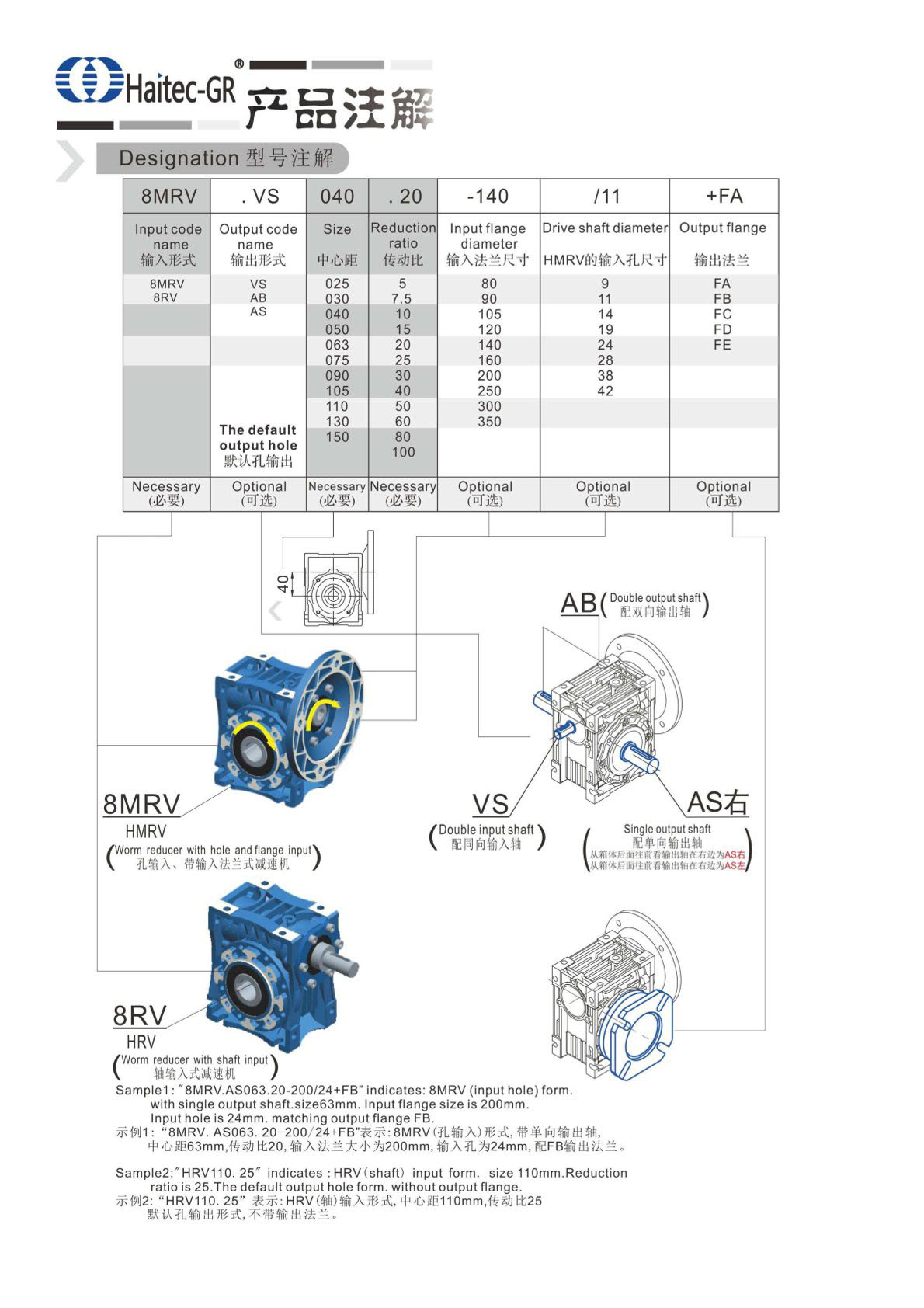

Designation 型號注解

8MRV | Worm geared motor 帶輸入法蘭式減速器(配合電機使用) | ||

8RV | Worm reduction unit 帶輸入軸式減速器 | ||

050 | Size 中心距 | ||

FA | Output flange 輸出法蘭 | ||

30 | Reduction ratio 傳動比 | D or S | Output flange mounting position 輸出法蘭的安裝型式 |

PAM | Fitted for motor coupling 帶輸入法蘭式減速器(配合電機使用,基本型) | ||

200 | Motor flange diameter 輸入法蘭尺寸 | 19 | Drive shaft diameter HMRV的輸入孔尺寸 |

VS | Double input shaft 配合向輸入軸 | AS | Single output shaft 配單向輸出軸 |

AB | Double output shaft 配雙向輸出軸 | B3 | Mounting position 安裝型式 |

0.75KW | Electric motor power 電機功率 | 4P | Electric motor polarity 電機極數 |

230/400V | Electric motor voltage 電機電壓 | 50HZ | Electric motor frequency 電機頻率 |

Performance 特性

Type of load 加于減速器的負荷性質 | Hours/day每日工作時數 | |||||

Starts/hour less than times 每小時間斷性操作次數少于10次 | Starts/hour more than ten times 每小時連續性或間斷性操作次數大于10次 | |||||

<2 | 2-8 | 8-24 | <2 | 2-8 | 8-24 | |

Service factor工作系數 | ||||||

Uniform 帶均衡負荷 | 0.8 | 1 | 1.25 | 1 | 1.25 | 1.75 |

Moderate 帶中級震蕩 | 1 | 1.25 | 1.5 | 1.5 | 1.75 | 2 |

Heavy shocks 帶重級震蕩 | 1.25 | 1.5 | 1.75 | 1.75 | 2 | 2.25 |